chemical cleaning of water and steam boilers

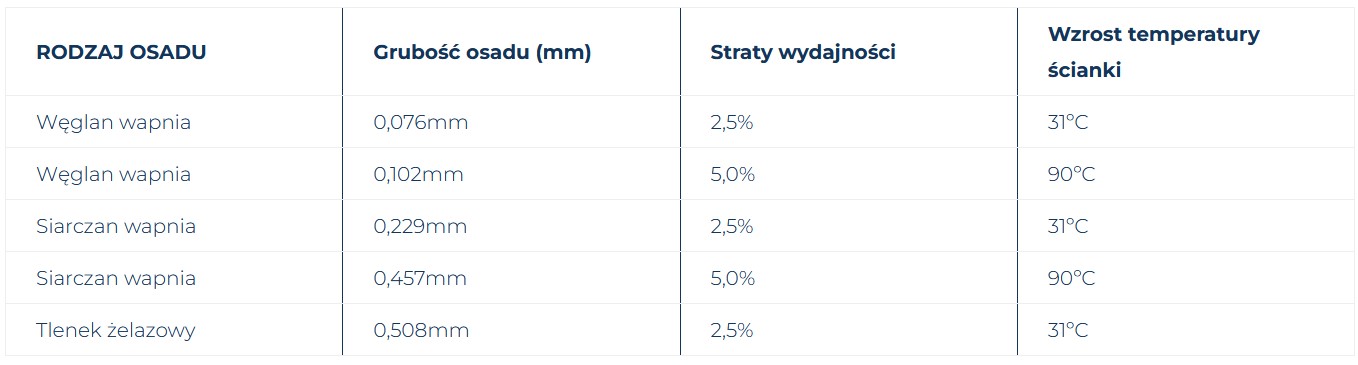

| Sediment type | Sediment thickness | Efficiency losses | Increase of wall temperature |

| Calcium Carbonate | 0,076mm | 2,5% | 31ºC |

| Calcium Carbonate | 0,102mm | 5,0% | 90ºC |

| Calcium Sulfate | 0,229mm | 2,5% | 31ºC |

| Calcium Sulfate | 0,457mm | 5,0% | 90ºC |

| Iron oxide | 0,508mm | 2,5% | 31ºC |

*) Ciepłownictwo.pl

Another example of contamination of new boiler with sediment is connecting it to old installation. Additional exchange of fueling pump can cause higher flow intensity, carrying over a sediment, which is usually a product of corrosion, from other parts of boiler installation system.

Contaminants of water used for boiler operation cause corrosion and limescale sedimentation on heat transfer surfaces. Just the presence of limscale is also a serious threat of corrosion for apparatus and installation system.

Regular cleaning of boilers in electric energy and heat plants a standard for a long time. In broadly defined industry and services this practice is largely omitted. Cleaning of boilers brings increase in safety, decrease on environmental hazards, and through decrease of fuel costs it becomes profitable. This is why chemical cleaning of boilers is recommended- it is a process that allows to maintain the optimal boiler state by reducing of exploitation costs. Regular cleaning of industrial boilers increases usage time without hazard of additional service costs or earlier exchange of damaged installation.

Regular cleaning of installation is a part of necessary prophylactics.

A question may arise “ why do some industrial plants neglect cleaning of boilers and “smoke their money up the chimney?”. There can be only one answer. A large number of users still wrongly assume that costs of cleaning are high at the same time forgetting about increasing cost of fuels. Contrary to assumptions investing in chemical cleaning is far more beneficial than buying larger amounts of fuels, which will go with smoke. Other users still think that chemicals can damage boilers. This can be contradicted by thousands of chemically cleaned boilers in Poland.

Application of chemical boiler cleaning and substituents bring measurable economic effects because of:

- Energy saving,

- Increase of installation efficiency,

- Decrease of damage,

- Elimination (complete or partial) of installation.

Results of abnormal exploitation are non-mechanical damage of boilers, one of many being over heating of metal due to sediment. This damages cause expensive apparatus repairs, their exchange and conduct of medium and capital renewals. Boiler degradation by mean of sedimentation leads to decrease of life time from 100 – 300%. Limescale may also cause damage of important boiler elements such as pumps, valves and pipes even if limescale is not sedimented directly in them. Layers of limescale cause decrease of heat exchange through walls of heated surfaces. This results in decrease of heat exchange coefficient and in turn decrease of boiler efficiency and excess fuel use.

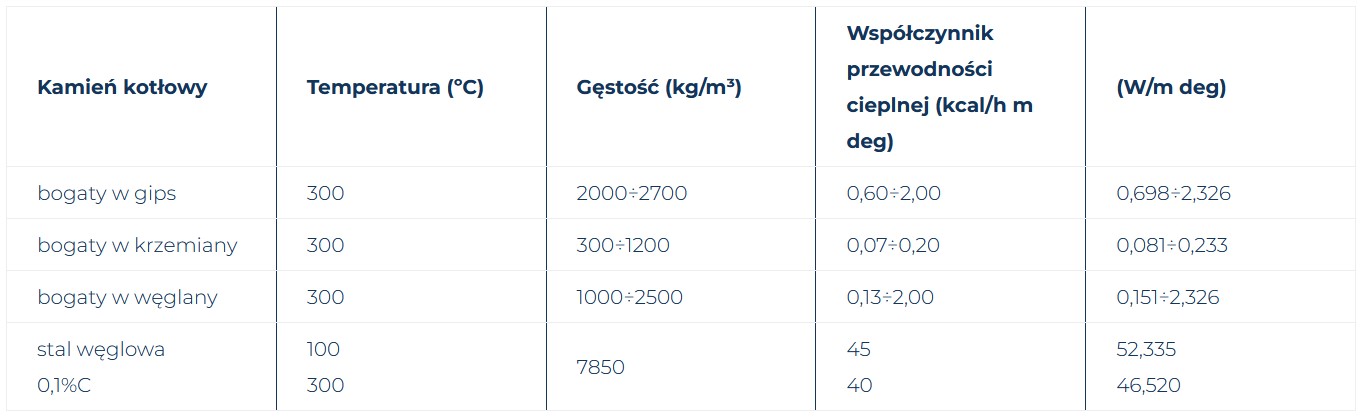

Table 2**) shows exemplary changes of heat conductivity of some types of limescale and carbon steel.

Tab.2**)

| Limescale | Temperature (ºC) | Density (kg/m³) | Heat conductivity coefficient (kcal/h m deg) | (W/m deg) |

| Gypsum | 300 | 2000÷2700 | 0,60÷2,00 | 0,698÷2,326 |

| Silica | 300 | 300÷1200 | 0,07÷0,20 | 0,081÷0,233 |

| Carbonate | 300 | 1000÷2500 | 0,13÷2,00 | 0,151÷2,326 |

| Carbon steel 0,1%C |

100 300 |

7850 | 45 40 |

52,335 46,520 |

**) K.Ražnjević „Tablice cieplne z wykresami”. Wyd. N-T. W-wa 1964

It can be noted that the worst limescale is 550 times less conductive than carbon steel.

The type of limescale sediment depends of many conditions such as chemical composition and density of water, heat intensity of heated surface and intensity of water evaporation.

Hard and dense limescale is created during slow evaporation, and soft limescale is created with fast evaporation. Gypsum very hard and very dense limescale is created on surfaces with high heat load. Silica limescale, of lowest heat conductivity, which is also most difficult in removal, is a hard and dense sediment. Speed of heat conduction is directly proportional to surface heat conductivity. Thus presence of any limescale on heat transfer surfaces can significantly decrease heat transfer speed with proportional increase of exhaust fumes temperatures.

It is not a surprise that limescale decreases efficiency of boilers and also of the heating process in central heating and water heating installations. Accumulation of limescale of 1mm thickness on transfer surface decreases its efficiency of about 10%, and in consequence increases fuel use. It is estimated that exploitations costs increase of boiler resulting from limescale production are about 20%.

One of often omitted symptoms of boiler work covered with limescale is increase of noise not connected with any damage like leakage or damage. It concerns mostly water boilers. In some parts of water boiler the water boils and in other parts due to condensation with current direction (implosion of vapor in water). This phenomenon is less volatile in warm or hot water. Those two phenomena are responsible for loud boiler work. In boilers with good isolation this warning signal may not be heard. Damaged boilers usually have a history of loud work and almost all of them have large amounts of sediment, not necessary in a place of fracture.

Many boilers accumulate sediments that cause waste of 10 to 35% fuel amount during only 5 years. This makes it close to complete damage of boiler. The cost of sediment boilers are hundreds millions of zlotys in the scale of a country. This concerns also thousands of water home use central heating installations. It is not a mistake if 10% average loss of fuel is estimated. With average gas use by a home boiler is assumed as 1500m3/year than 300 PLN of annual savings can be reached. Saving of fuel with maintain of internal boiler cleanness is less costly than other means of fuel saving.

Recommendations for all users of boilers are:

- Monitoring of exhaust fumes temperatures.

- Maintenance of boiler cleanness.

Advantages of chemical cleaning:

- High efficiency; sediments are dissolved fast,

- Relatively low operation costs,

- Speed of operation,

- Safe for humans and installation.

We offer complex services in cleaning devices and installations with use of state of the art technologies. We supply necessary chemicals and equipment.

To maximize the cleaning effect for every type of device and sediment an individual technology based on laboratory research is applied. Inhibitors used by us effectively secure device construction material from corrosion.

Our company is in the business for 30 years. Our experience counts.

Our company has done 600 cleanings thus far.

Ogrzewania i Naprawy Kotłów - Styczeń Spółka Cywilna

ul. Partyzantów 26/10, 26-300 Opoczno

Phone/Fax:

(+48) 48-36-517-82

Mobile Phone:

(+48) 508-823-857

(+48) 608-393-294